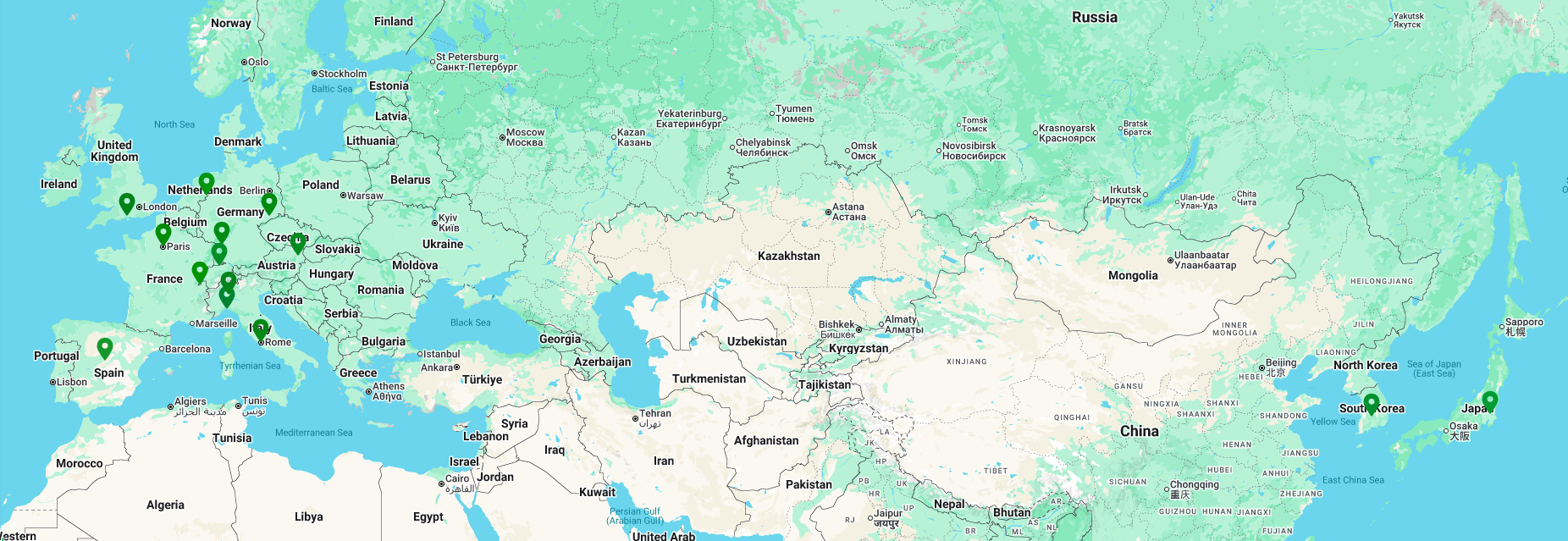

Existing collaboration Institutes

|

Institution & Link |

Logo |

Activities |

|

|

Characterization of the internal oxidation path in Nb3Sn to increase the critical current. Experiments in model samples and wires are utilized to gain insights into the phase transformations involved. |

|

|

|

Demonstrate enhanced critical current density in Nb3Sn wires through internal oxidation and APC using fabrication methods suitable for industrial production.

|

|

|

Measure the electromechanical limits of commercial and R&D Nb3Sn wires through tests simulating operational constraints in accelerator magnets. |

||

|

|

Manufacturing and developing REBCO tapes for high field magnets in particle accelerators. |

|

|

|

Development of a test rig for a systematic study of bonding and delamination issues in ReBCO Roebel cables samples including a first demonstration test at 77 K. |

|

| CNR-SPIN | Development of HTS iron-based superconducting conductors for the high-field magnet (HFM) R&D programme. | |

|

|

Design and manufacturing 12 T two-layer cos theta dipoles. Design and manufacturing 14 T four-layer cos theta dipoles. Design and manufacturing HTS dipoles based on REBCO tapes targeting 10 T in 50 mm aperture at 10 K.

|

|

|

|

Studying the metal insulated path with REBCO tapes for high field accelerator dipoles based on racetrack coils. |

|

|

Design and manufacture demonstrators and short models (R2D2, FD, F2D2) for 12-14 T Nb3Sn dipole based on block coils and grading.

|

||

|

|

Design and manufacture demonstrators and short models (ISAAC, DAISY) for 12-14 T Nb3Sn dipole based on common coil design, including grading with Nb-Ti.

|

|

|

|

Design and manufacture subscale demonstrators (subSMCC and subSMACC) and short models (SMACC) for 12–14 T Nb₃Sn dipoles based on a stress-managed common-coil design, including grading with Nb-Ti, ESC-based protection, and 4.5 K conduction cooling through forced flow.

Develop HTS REBCO-based subscale dipole magnets using a common-coil design and test REBCO-based cables under background field.

|

|

|

|

Characterization of HTS conductors at low temperatures. |

|

|

To develop and industrialize advanced high-field Nb3Sn conductors achieving HL-LHC Jc of 1200 A/mm² at 4.2 K and 16 T.

|

||

|

Characterization and modeling of REBCO tapes and cables for magnetisation current distributions and ac losses. Development of insulated REBCO winding technology. Manufacturing of a 10 T solenoid to be integrated in existing solenoids used for tests.

|